FEATURED

MISHPOCHA WOODS COMPOUND Austin TX

LowDO bridges design and construction; we often execute projects as design-build, a process in which we continue beyond architectural design services to also manage construction of a project. The Mishpocha Woods Eco-Compound is an example of what we refer to as “extreme design build,” when we empower the client to be the builder and to run construction as we share our guidance.

We believe that architecture can become more inclusive by focusing on participation, and that buildings are a means to an end, not an end in themselves....

moreENVIROMOLECULAR Venice Architecture Biennale

“Enviromolecular” refers to basic structure for life support and a “chemical” approach to building dynamic space. Atoms conjoin periodically to form molecules, minimum microstructures capable of performing a material’s chemical behavior – how matter interacts, electronically – enabling quantum effects to register harmonically at human-scale.

2023 exhibit in the Dangerous Liasons section of the Arsenale

moreDAKOTA MOUNTAIN Dripping Springs TX

Designed and built by LowDO on a three-acre property in the Texas hill country, the Dakota Mountain Residence is a homestead that pilots sustainability for contemporary lifestyles. A retired couple wanted to build a climate-responsive house tailored for their creative pursuits, and to host their children and grandchildren. The project emerged accordingly as a form of intermittent intra-family co-housing, interlocking two homes into a single block.

2019 [design and construction by LowDO]

2020 AIA Austin Design Award Commendation: Sustainability

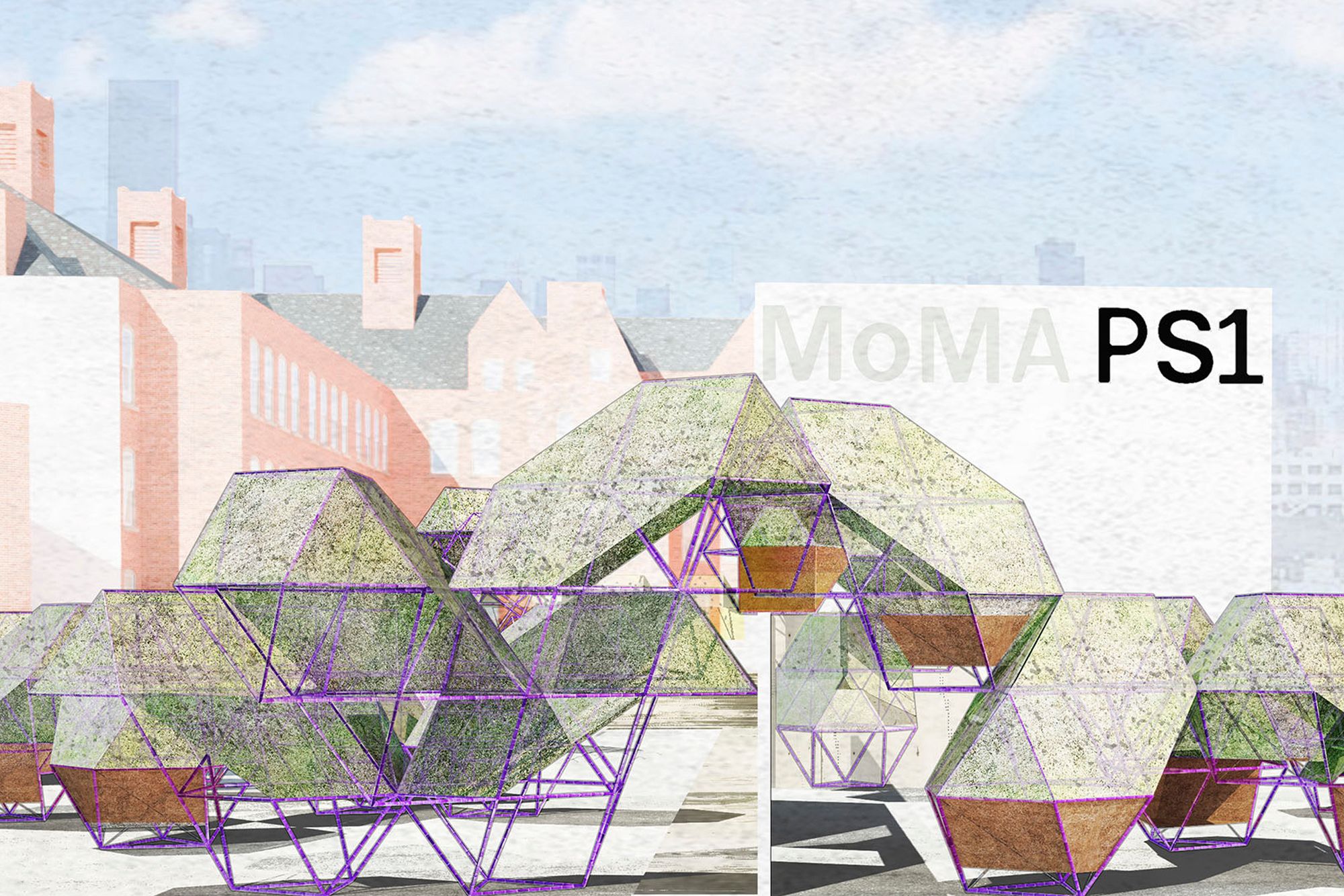

BAMBOT: FUFUZELA MoMA PS1 YAP

FUFUZELA are free modular mobile #BAMBOTS (bamboo micro-infrastructure) that interoperate at the scale between furniture and architecture. Designed for self-assembly, fufuzela are—like deer and sheep—irregular plurals that are simultaneously one and many. In a world at war with itself, how can we accommodate the multiplicity of a multicultural multiverse? Fufuzela create scaffolding for shared experience: By embodying material ecologies of symbiosis, fufuzela enable new forms of...

moreRIVER HOUSE New Braunfels TX

Three siblings use this 2900sf home as a gathering point for their families. They asked that the design create a space that promotes and emphasizes connections 1) between the families, 2) to light and the surrounding landscape, and 3) to the river. Additionally, the house needed to be built on a very tight budget-- no simple feat for a site within the Guadalupe River Floodway. To achieve these demands, we focused design around standard materials, details, and components while emphasizing dramatic spatial configurations at connection points that would enhance shared moments between the...

moreBEAUREGARD HOUSE San Antonio TX

The Beauregard House is a transitional building, designed around ideas of salvage / revitalize / reinterpret. The transitional nature of the design allows it to serve its multiple functions of home, office, and vacation rental.

The house embraces the peace and quiet beauty of a house built in 1900—a grand structure surrounded by a lush neighborhood—even as it becomes a 21st century space in an ever more...

moreAMP SPACECRAFT Accra GH

Agbogbloshie Makerspace Platform (AMP) is a pan-African participatory design initiative to build alternative futures, cooperatively—networking the practical know-how of grassroots makers with the technical knowledge of students and young professionals in STEAM fields (Science, Technology, Engineering, Arts and Mathematics). Working in and around the Agbogbloshie scrapyard in Ghana’s capital, Accra, over 2000 youth from West Africa, Europe and the United States have collaborated over seven years to iteratively design...

moreGARDEN STREET HOUSE Austin TX

This house weaves green building and contemporary design into the context of its Austin, Texas neighborhood -- on a budget. It was conceived as a framing system for the lives of those within, using a variety of implicit framing devices at different scales to create subtly distinct moments that can be experienced separately or simultaneously.

2012 [design and construction by LowDO]

- 2013 Featured residence, Austin Modern Homes Tour

- 2013...

BAMBOO LATTICE VAULT Accra GH

Commission for the opening of contemporary African art Gallery1957 at the ANO Institute in Accra, Ghana. The design brief called for a long canopy to host a lunch-time meal and conversation. However, at the time of installation the question was posed: Can the canopy instead simple create an entry into the ANO courtyard? This was accomplished by means of a lightweight lattice vault woven from split bamboo, installed over 24 hours as a...

more